Products

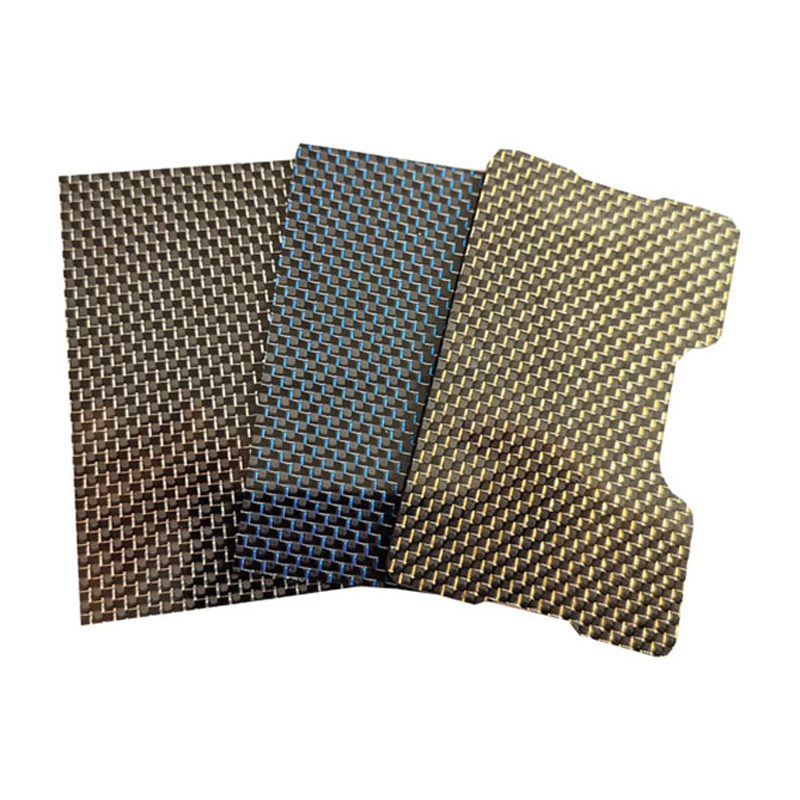

Special Design for Carbon Fiber Bag - Cnc custom Carbon Fiber Kevlar Sheets Rc Airplane Prepreg – Snowwing

Special Design for Carbon Fiber Bag - Cnc custom Carbon Fiber Kevlar Sheets Rc Airplane Prepreg – Snowwing Detail:

Products Categories

Carbon Sheet Description

Carbon fiber has a leading position in the market for manufacturing composite materials. The laminate features light weight, strength and a unique luxurious appearance.

We manufacture and supply carbon fiber components and products. Our offer includes formed carbon fiber parts as well as carbon fiber sheets.

All carbon fiber parts and products are manufactured with high quality epoxy resins. We can manufacture products according to your specific quality and strength parameters.

Dimension Table

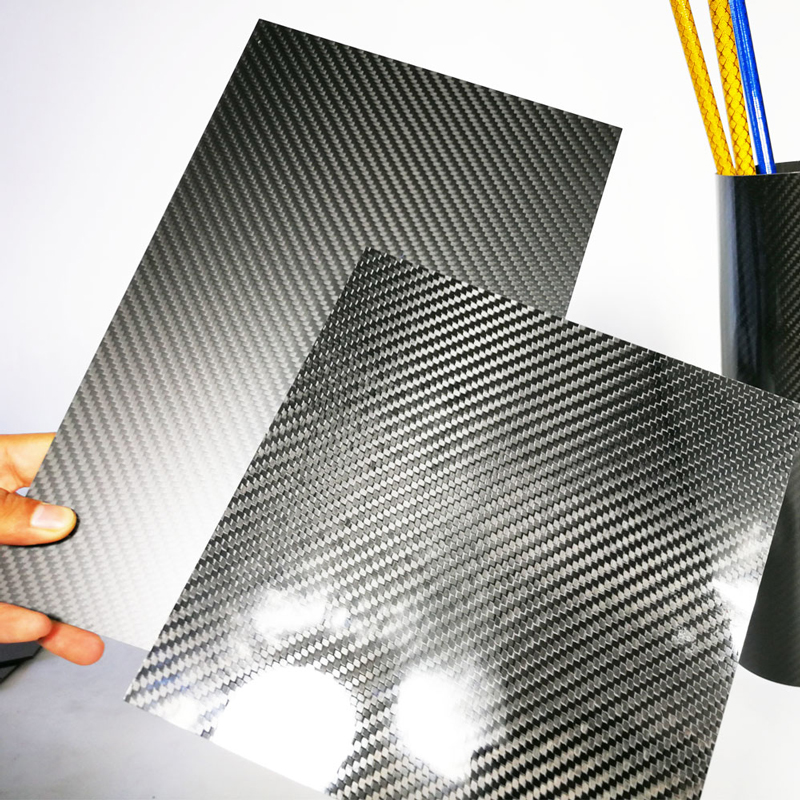

| Product name | High quality 0.5mm 1mm 2mm 5mm 10mm carbon panels carbon fiber plates sheets |

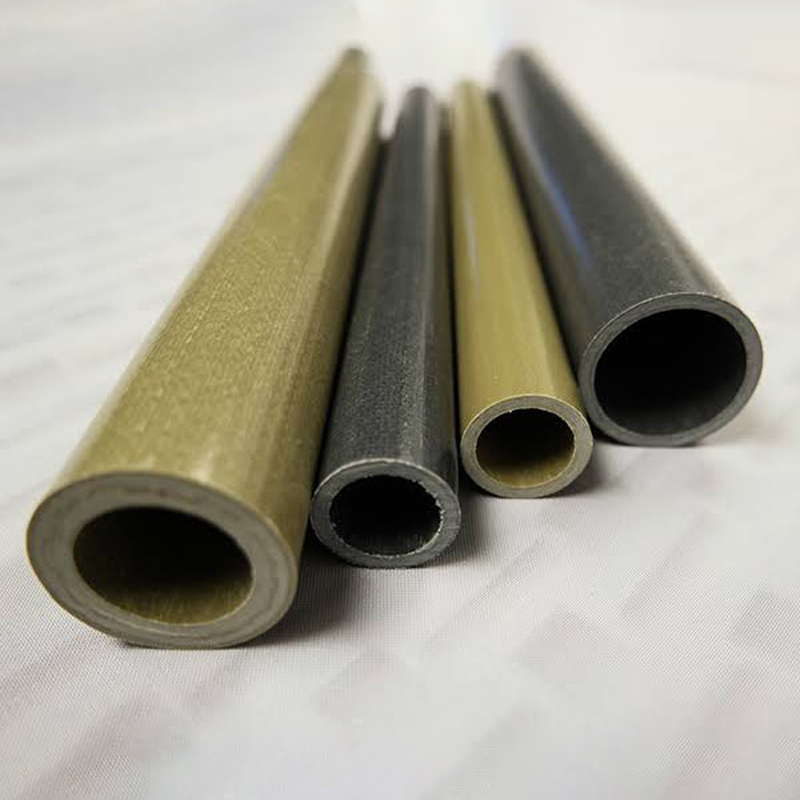

| Material | Full carbon fiber, or carbon fiber + fiberglass |

| Size | as requested |

| Surface | Glossy/ Matte finished |

| Weave | 3K Plain / 3K Twill / Unidirection |

| Accessory | customzied as individual requirement |

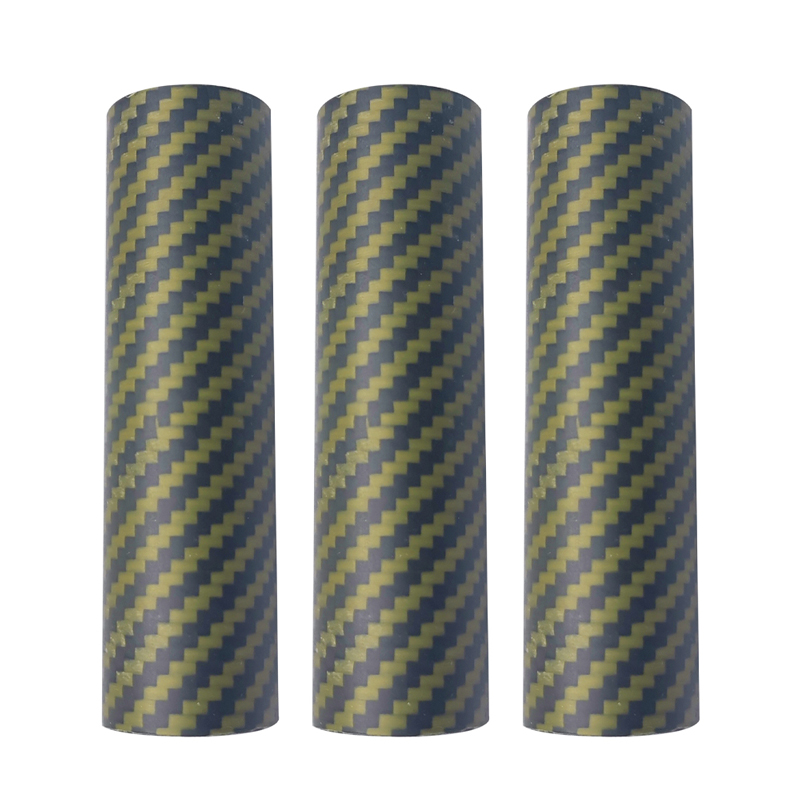

Product Picture Display

Production Process

Customization – prepreg plies can readily be added or subracted allowing the tube to be customized with different wall thicknesses

Sample acceptable – Because each carbon sheet and carbon tube is made one at a time, small production runs are available.

CNC machining — cutting according to your CAD drawing

Print logo – according to AI file

One-stop procurement – whole industry chain of carbon fiber composite products

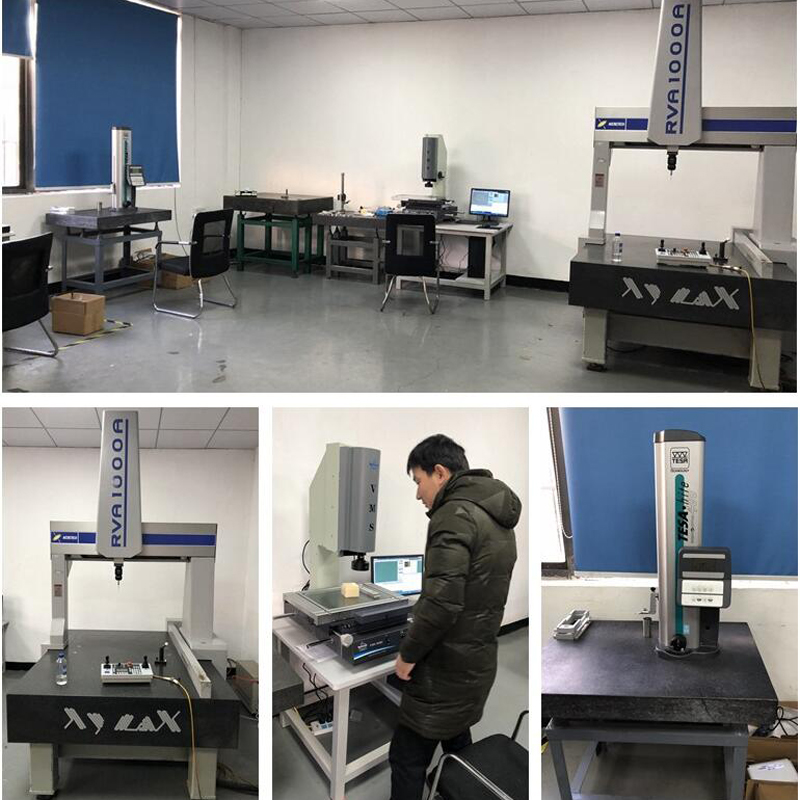

Quality Control

CARBON FIBER SHEET PLATE QUALITYWe have professional QC to check quality.

Raw material is Japan level carbon fiber

Surface is clear

Making according to customer drawing

Good package

Customer Praise

WELCOME TO CONTACT US TO GET SAMPLES TO TEST.

Product detail pictures:

Related Product Guide:

Our commission would be to serve our customers and clientele with very best excellent and aggressive portable digital products for Special Design for Carbon Fiber Bag - Cnc custom Carbon Fiber Kevlar Sheets Rc Airplane Prepreg – Snowwing , The product will supply to all over the world, such as: Istanbul, Montreal, Indonesia, Selling our products causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

We are a professional chinese manufacturer of carbon fiber.and also carbon fiber products for more than 10 years!

we produce alltype carbon fiber tubes,panel,bars,rods,CNC sheet Etc excellent properties include: corrosion resistance lightness good toughness If you want order our products, please include ID, OD, length, dimensional tolerances, quantity, structural requirements, surface finish, surface pattern, material (if you know), temperature requirements, pocesing technology etc. With these items as the starting point, we can usually very quickly put together a quotation to help you get your project from idea to reality.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.