Carbon fiber refers to high-strength and high-modulus fibers with a carbon content of more than 90%. High temperature resistance ranks first among all chemical fibers. It is made of acrylic fiber and viscose fiber, which is oxidized and carbonized at high temperature. It is an excellent material for manufacturing aerospace and other high-tech equipment

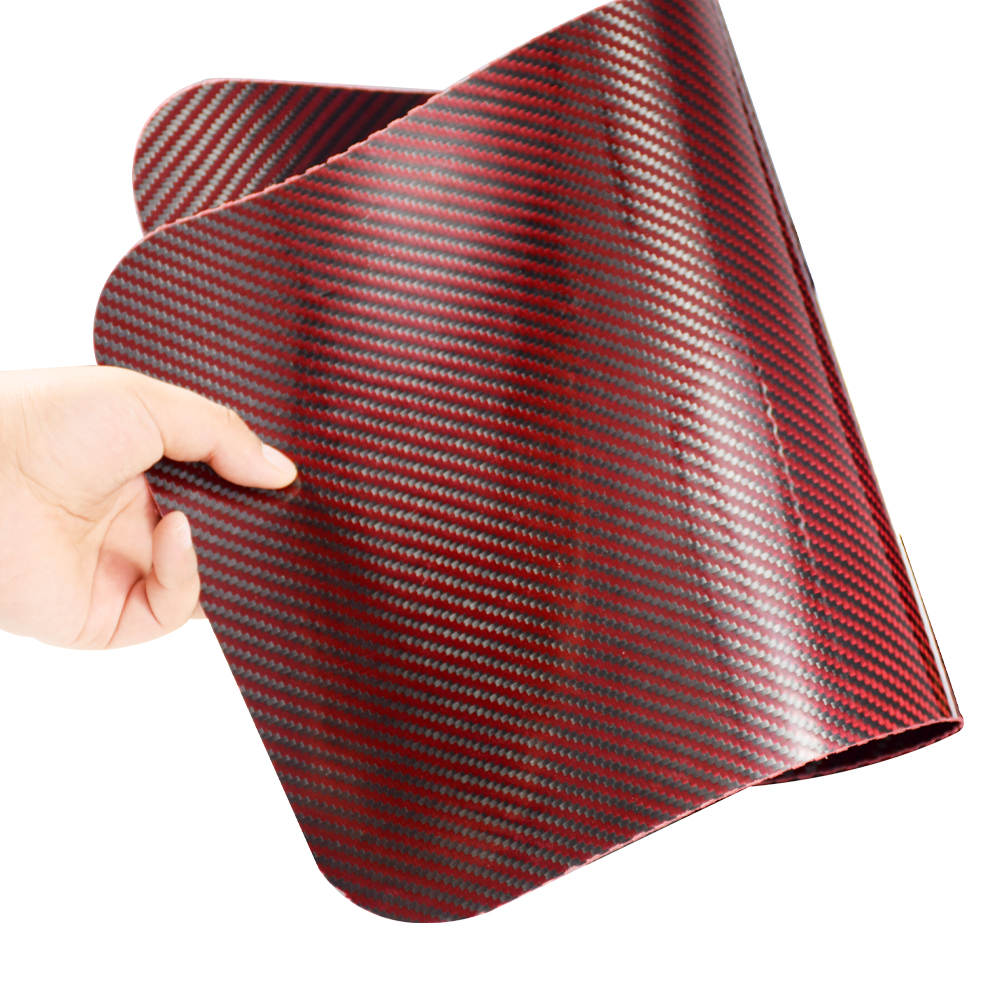

Carbon fiber is mainly composed of carbon elements, and has the characteristics of high temperature resistance, friction resistance, thermal conductivity and corrosion resistance. The shape is fibrous, soft, and can be processed into various fabrics. Orientation has high strength and modulus. The density of carbon fiber is low, so the specific strength and specific modulus are high. The main use of carbon fiber is as a reinforcing material to be compounded with resin, metal, ceramic and carbon to manufacture advanced composite materials. Carbon fiber reinforced epoxy resin composites have the highest specific strength and specific modulus among existing engineering materials.

In 1879, Edison used cellulose fibers, such as bamboo, flax or cotton yarn as raw materials, and first obtained carbon fibers and obtained a patent. However, the mechanical properties of the fibers obtained at that time were very low, and the process could not be industrialized, so it failed to develop.

Significant progress has been made in asphalt science since 1981, and several new processes for preparing mesophase asphalt have been developed, such as the pre-mesophase method of Kyushu Industrial Laboratory in Japan, the new mesophase method of EXXON Corporation of the United States, and the potential intermediate phase method developed by Gunma University in Japan. The phase method promotes the development of high-performance pitch-based carbon fibers. Subsequently, Japan's Mitsubishi Chemical Corporation, Osaka Gas Corporation, and Nippon Steel Corporation successively built a number of high-performance carbon fiber production plants of different specifications. Its characteristic is that the modulus increases while also increasing the strength. The 1980s was a boom period for pitch-based carbon fibers

The name of the fibril used for the manufacture of carbon fiber Chemical composition Carbon c ontent/% Carbon fiber yield/% Viscose fiber (C6H10O5) n4521~35 Polyacrylonitrile fiber (C3H3N) n6840~55 Pitch fiber C, H9580~90

ontent/% Carbon fiber yield/% Viscose fiber (C6H10O5) n4521~35 Polyacrylonitrile fiber (C3H3N) n6840~55 Pitch fiber C, H9580~90

Common Uses of Carbon Fiber

- High-end automobile components

- Bicycle frames

- Fishing rods

- Shoe soles

- Baseball bats

- Protective cases for laptops and iPhones

More exotic uses can be found in the:

- Aeronautics and aerospace industries

- Oil and gas industry

- Unmanned aerial vehicles

- Satellites

- Formula-1 race cars

Some would argue, though, that the possibilities for carbon fiber are limited only by demand and the manufacturer’s imagination. Now, it’s even common to find carbon fiber in:

- Musical instruments

- Furniture

- Art

- Structural elements of buildings

- Bridges

- Wind turbine blades

Post time: Jun-27-2022