The route of modern carbon fiber industrialization is the precursor fiber carbonization process. The composition and carbon content of the three raw materials used are shown in the table.

The name of the fibril used for the manufacture of carbon fiber Chemical composition Carbon content/% Carbon fiber yield/% Viscose fiber (C6H10O5) n4521~35 Polyacrylonitrile fiber (C3H3N) n6840~55 Pitch fiber C, H9580~90

The process of making carbon fibers from these three kinds of fibrils includes: stabilization treatment (air at 200-400℃, or chemical treatment with flame-retardant reagents), carbonization (400-1400℃, nitrogen) and graphitization (above 1800℃) , under an argon atmosphere). In order to improve the adhesion between carbon fiber and composite matrix, it is necessary to carry out surface treatment, sizing, drying and other processes.

Another method of making carbon fibers is vapor growth. In the presence of a catalyst, the mixed gas of methane and hydrogen is reacted at a high temperature of 1000°C to obtain discontinuous chopped carbon fibers with a maximum length of 50 cm. Its structure is different from polyacrylonitrile-based or pitch-based carbon fibers, easy to graphitize, good mechanical properties, high electrical conductivity, and easy to form interlayer compounds. (see Vapour Growth Carbon Fibers)

Classification and naming

At present, the main products of carbon fiber are polyacrylonitrile, pitch and viscose. The word “carbon fiber” is actually a general term for a variety of carbon fibers, so classification and naming are very important.

In the late 1970s, the International Union of Theoretical and Applied Chemistry (IUPAC) regulated the classification and naming of carbon fibers. First, use PAN (polyacrylonitrile), MP (mesophase pitch) and VS (viscose) to indicate the type of carbon fiber, and then use lowercase English letters to indicate the heat treatment temperature, such as lht (indicates heat treatment temperature, below 1400 ℃), hht (heat treatment temperature) The temperature is above 2000 °C), and then add the symbol representing the performance (such as HT for high strength, HM high modulus, SHT ultra-high strength, HTHS high strength and high strain, IM medium mode and UHM ultra-high mode, etc.). At the same time, it is pointed out that polyacrylonitrile-based, viscose-based and common pitch-based carbon fibers are all polymer carbons that are difficult to graphitize, while mesophase pitch-based carbon fibers and vapor-grown carbon fibers are easily graphitizable carbons.

At the Third International Carbon Fiber Conference (London, 1985), it was proposed to classify carbon fibers into the following 5 grades according to their mechanical properties.

Ultra-high modulus (UHM): the modulus is above 395GPa;

High modulus (HM): the modulus is between 310 and 395GPa;

Intermediate modulus (IM): the modulus is between 255 and 310GPa;

Ultra-high strength grade (UHT): the strength is above 3.5GPa,

Modulus below 255GPa;

High Strength Grade (HT): Strength up to 3.5GPa.

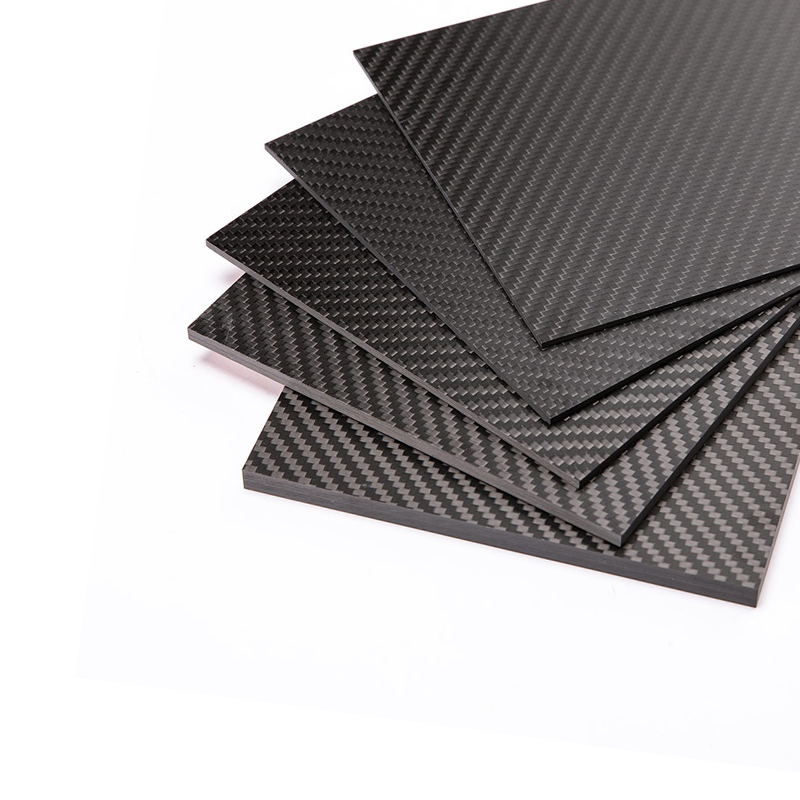

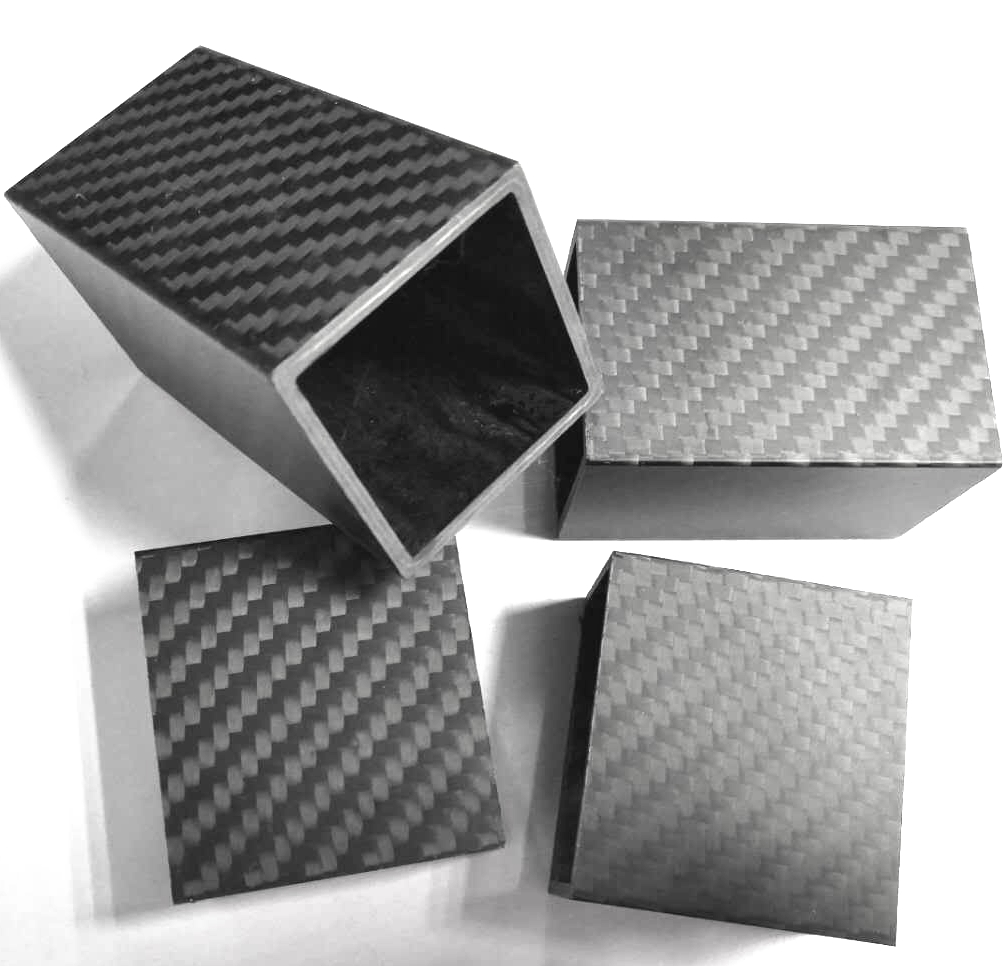

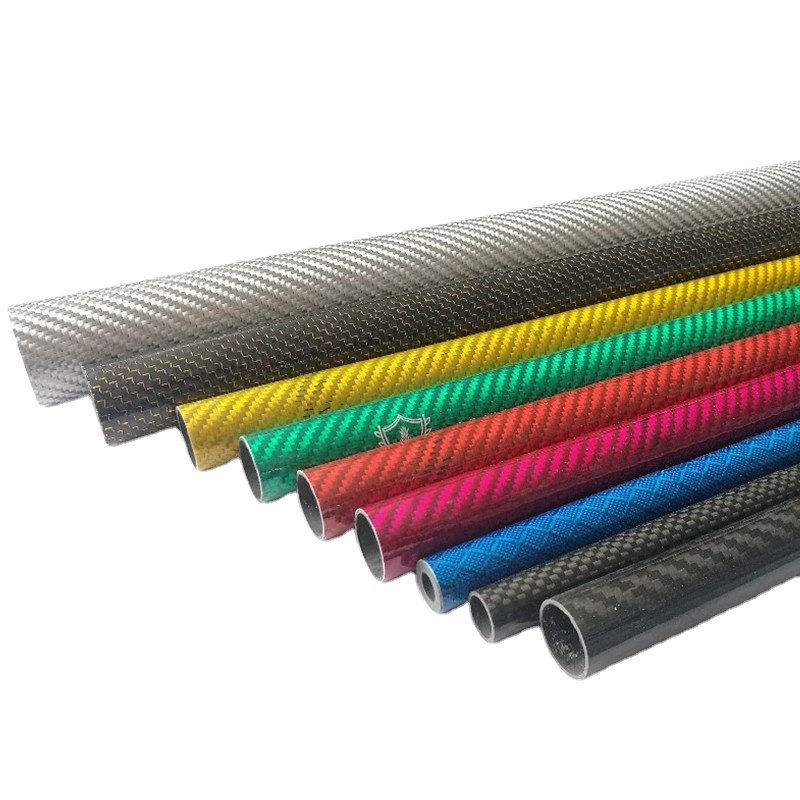

Both classification methods have shortcomings. At present, the classification of high-performance carbon fiber products is indicated by the manufacturer: the type of fibril, the number of monofilament holes, diameter, arrangement (such as parallel, entangled, twisted, etc.), with or without surface treatment (and its type), with or without sizing (and the type of slurry), etc. Some important high-performance trade names and properties can be seen in polyacrylonitrile-based carbon fibers and pitch-based carbon fibers.

Post time: Sep-17-2022