Carbon fiber industry has a bright future

Carbon fiber industry has a bright future

As the “king of new materials” in the 21st century, carbon fiber can achieve the replacement of traditional materials such as steel and aluminum alloy, and has a broad market prospect. Although China’s carbon fiber research started earlier, but for a long time, the problem of scattered R & D forces, low-level duplication and serious construction has been a “roadblock” to the high-end transformation of the industry. Entering the “12th Five-Year Plan”, China’s carbon fiber industry has ushered in a broader space for development, policy energy continues to be released, innovation capabilities continue to improve, a flourishing new industry is rising

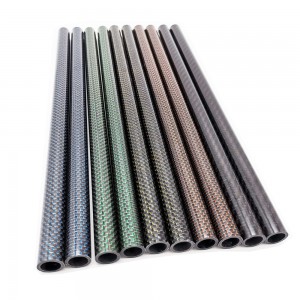

The total length of 18.91 kilometers of the country’s first stranded carbon fiber core aluminum strand – 220 kV Fofeng I line recently in Hainan test delivery success, this is the first time in China carbon fiber cable line for overhead lines. The success of the grid transformation project opened up another important application area of carbon fiber. Tuan Xiaoping, president of China Chemical Fiber Industry Association, said, “In recent years, carbon fiber has been successfully applied in many industrial fields, indicating that there is a broad market space for carbon fiber applications.”

Translated with www.DeepL.com/Translator (free version)

Huge room for substitution

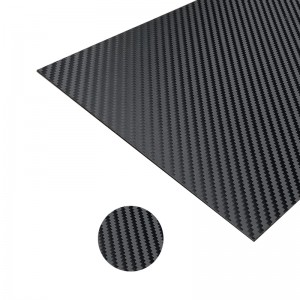

The replacement of traditional materials such as steel and aluminum alloy is the main driving force for the promotion of carbon fiber applications. Because of its light weight, high temperature resistance, corrosion resistance and other excellent properties, carbon fiber has a very broad market prospect and can be widely used in petrochemical, aerospace, sporting goods, transportation and other fields

It has superior physical and chemical properties. Its weight is less than a quarter of steel, but its tensile strength is seven to nine times that of steel, and its tensile elasticity, specific strength, and specific modulus are significantly better than steel, and it also has the advantages of high temperature resistance and corrosion resistance. These excellent properties give carbon fiber a broad market prospect, is widely used in petrochemical, aerospace, sporting goods, transportation and other fields

The replacement of traditional materials such as steel and aluminum alloy is the main driving force for the promotion of carbon fiber applications. Experts say that “plastic instead of steel” is the inevitable trend of the 21st century, and promoting the light weight of cars, aircraft and other products to reduce fuel consumption and meet the serious challenges of resources and the environment has become an important theme of industrial development.

Airbus A380, for example, because each aircraft using carbon fiber composite reinforced materials to 21 tons to 25 tons, so that each passenger 100 kilometers of fuel consumption of less than 3 liters, is currently the world’s first passenger per 100 kilometers of fuel consumption of less than 3 liters of long-range passenger aircraft, seat mile cost than the most efficient aircraft is currently 15% to 20% lower, its fuel economy than the corresponding competitive models to about 13% lower.

“The key to the replacement of traditional materials is to consider the cost factor, and if the cost is the same, users are willing to choose carbon fiber with better performance.” Duan Xiaoping said. In terms of cost reduction, China’s carbon fiber research and development production has played a major role. 2008, when Chinese enterprises announced the large-scale production of T300 carbon fiber, the international price of this specification product dropped from 500 yuan per kilogram to less than 120 yuan; in 2012, when the high-performance T700 grade carbon fiber was successfully experimented in China, the international price of this specification product dropped from 400 yuan per kilogram to 160 yuan. In 2012, when the high performance T700 grade carbon fiber was successfully experimented in China, the international price of this specification dropped from 400 RMB to 160 RMB per kg.

Along with the trend of low cost, the application of carbon fiber in automobiles, aerospace vehicles and various mechanical equipment is growing rapidly, and the global consumption of carbon fiber is expected to reach 70,000 tons by 2015, with a compound annual growth rate of 9.37%. By 2020, the global demand for carbon fiber could even reach 130,000 tons/year.

“This is undoubtedly a big piece of cake, but at present, China can get very little from it, and most of it relies on imports.” Jianbo Gou, a researcher at the Institute of Industrial Planning of the China Institute of Machinery (Department of) Information Technology, said. China’s production and use of carbon fiber is still in its infancy, mainly small filament bundles, quality close to or up to the level of T300, and unstable, and foreign advanced level is still a gap, resulting in restricted applications, the market size is narrow.

Therefore, to improve the quality of products to replace imports, is of great significance. No Jianbo said, now the country proposed to vigorously develop independent carbon fiber industry, encourage the mastery of key core technology, improve the carbon fiber self-sufficiency rate, “with the breakthrough of China’s core technology and policy support, the future of domestic carbon fiber will gradually replace imported products, domestic carbon fiber will usher in greater opportunities for development

Post time: Oct-22-2022