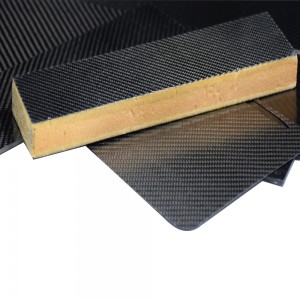

Application of carbon fiber products

In fiber reinforced composites, fiberglass is the “workhorse” of the industry. It is used in many applications and is very competitive with traditional materials such as wood, metal, and concrete. Fiberglass products are strong, lightweight, non-conductive, and the raw material costs of fiberglass are very low.

In applications where there is a premium for increased strength, lower weight, or for cosmetics, then other more expensive reinforcing fibers are used in the FRP composite.

Aramid fiber, such as DuPont’s Kevlar, is used in an application that requires the high tensile strength which aramid provides. An example of this is body and vehicle armor, where layers of aramid reinforced composite can stop high powered rifle rounds, due in part to the high tensile strength of the fibers.

Carbon fibers are used where low weight, high stiffness, high conductivity, or where the look of the carbon fiber weave desired.

Carbon Fiber In Aerospace

Aerospace and space were some of the first industries to adopt carbon fiber. The high modulus of carbon fiber makes it suitable structurally to replace alloys such as aluminum and titanium. The weight savings carbon fiber provides is the primary reason carbon fiber has been adopted by the aerospace industry.

Every pound of weight savings can make a serious difference in fuel consumption, which is why Boeing’s new 787 Dreamliner has been the best-selling passenger plane in history. The majority of this plane’s structure is carbon fiber reinforced composites.

Sporting Goods

Recreational sports is another market segment which is more than willing to pay more for higher performance. Tennis rackets, golf clubs, softball bats, hockey sticks, and archery arrows and bows are all products commonly manufactured with carbon fiber reinforced composites.

Lighter weight equipment without compromising strength is a distinct advantage in sports. For example, with a lighter weight tennis racket, one can get much faster racket speed, and ultimately, hit the ball harder and faster. Athletes continue to push for an advantage in equipment. This is why serious bicyclists ride all carbon fiber bikes and use bicycle shoes that use carbon fiber.

Wind Turbine Blades

Although the majority of wind turbine blades uses fiberglass, on large blades (often over 150 ft in length) include a spare, which is a stiffening rib that runs the length of the blade. These components are often 100% carbon, and as thick as a few inches at the root of the blade.

Carbon fiber is used to provide the necessary stiffness, without adding a tremendous amount of weight. This is important because the lighter a wind turbine blade is, the more efficient it is at creating electricity.

Automotive

Mass-produced automobiles are not yet adopting carbon fiber; this is because of the increased raw material cost and necessary changes in tooling, still, outweighs the benefits. However, Formula 1, NASCAR, and high-end cars are using carbon fiber. In many cases, it is not because of the benefits of properties or weight, but because of the look.

There are many aftermarket automotive parts being made out of carbon fiber, and instead of being painted, they are clear-coated. The distinct carbon fiber weave has become a symbol of hi-tech and hi-performance. In fact, it is common to see an aftermarket automotive component that is a single layer of carbon fiber but has multiple layers of fiberglass below to lower costs. This would be an example where the look of the carbon fiber is actually the deciding factor.

Although these are some of the common uses of carbon fiber, many new applications are seen almost daily. The growth of carbon fiber is fast, and in just 5 years, this list will be much longer.

Post time: Feb-11-2023