Products

New Arrival China Carbon Fiber Tube 19mm - Carbon Fiber Solid Tube Pultruded Carbon Fiber Rod Pipe – Snowwing

New Arrival China Carbon Fiber Tube 19mm - Carbon Fiber Solid Tube Pultruded Carbon Fiber Rod Pipe – Snowwing Detail:

Products Categories

Carbon Tube Description

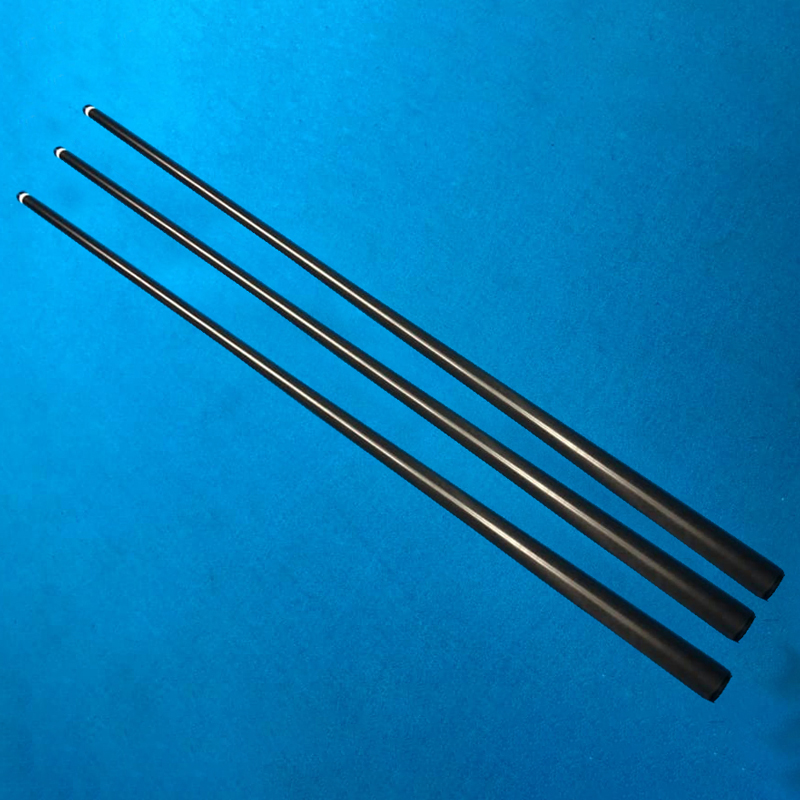

Our Carbon Fiber Solid Rods are manufactured by a pulling continuous carbon fibers combined with a resin matrix through a heated steel forming die. This process is referred to as pultrusion and is used for producing continuous lengths of composite materials with constant cross-sections.

As the carbon fibers are saturated with the resin mixture and then pulled through a round die, the hardening of the resin is initiated by the heat from the die and a rigid, cured structure is formed in the shape and size of the die. The majority of the fibers are running in the 0 degree direction, along the length of the tube, to produce an extremely stiff and lightweight rod with a very low coefficient of expansion. This type of construction offers a high stiffness to weight ratio rod with incredible linear strength, due to the orientation of the carbon fibers, and tight outer diameter (OD) tolerances.

Our Carbon Fiber Solid Rods have a matte finish surface and are easily bondable.

Dimension Table

| 5*4 | 12*11 | 16*11 | 18*17 | 20*20 | 25*13 | 29*27 | 36*34 |

| 6*4 | 13*10 | 16*12 | 19*11 | 22*16 | 25*15 | 30*22 | 37*29 |

| 6*5 | 13*11 | 16*13 | 19*12 | 22*17 | 23*19 | 30*23 | 37*33 |

| 7*4 | 14*8 | 16*14 | 19*13 | 22*18 | 25*20 | 30*25 | 37*34 |

| 7*5 | 14*10 | 16*15 | 19*14 | 22*19 | 25*21 | 30*26 | 38*35 |

| 7*6 | 14*11 | 17*7 | 19*15 | 22*20 | 25*22 | 30*27 | 40*38 |

| 8*6 | 14*12 | 17*13 | 19*16 | 22*21 | 25*23 | 30*28 | 42*40 |

| 9*7 | 14*13 | 17*14 | 19*17 | 23*14 | 26*23 | 31*30 | 43*41 |

| 9*8 | 15*10 | 17*15 | 19*18 | 23*19 | 26*24 | 31.7*33.38 | 50*47 |

| 10*8 | 15*11 | 18*10 | 20*12 | 23*21 | 26*25 | 32*30 | |

| 10*9 | 15*12 | 18*11 | 20*14 | 24*16 | 28*24 | 33*31 | |

| 12*6 | 15*13 | 18*12 | 20*16 | 24*18 | 28*25 | 35*30 | |

| 12*8 | 15*14 | 18*14 | 20*17 | 24*19 | 28*26 | 35*31 | |

| 12*9 | 16*8 | 18*15 | 20*18 | 24*20 | 28*27 | 35*33 | |

| 12*10 | 16*10 | 18*16 | 20*19 | 24*22 | 29*26 | 36*33 | |

|

Length:max length can make 4000mm |

|||||||

|

max OD diameter can make 400mm |

|||||||

Product Picture Display

Application

Uses Include Aerospace Spars & Beams UAV Components Frames & Supports Structural Components Interior Design

Automation Equipment Recreational Equipmen R/C Applications

Quality Control

CARBON FIBER TUBE QUALITY CONTROL

All raw material is Japan level carbon fiber

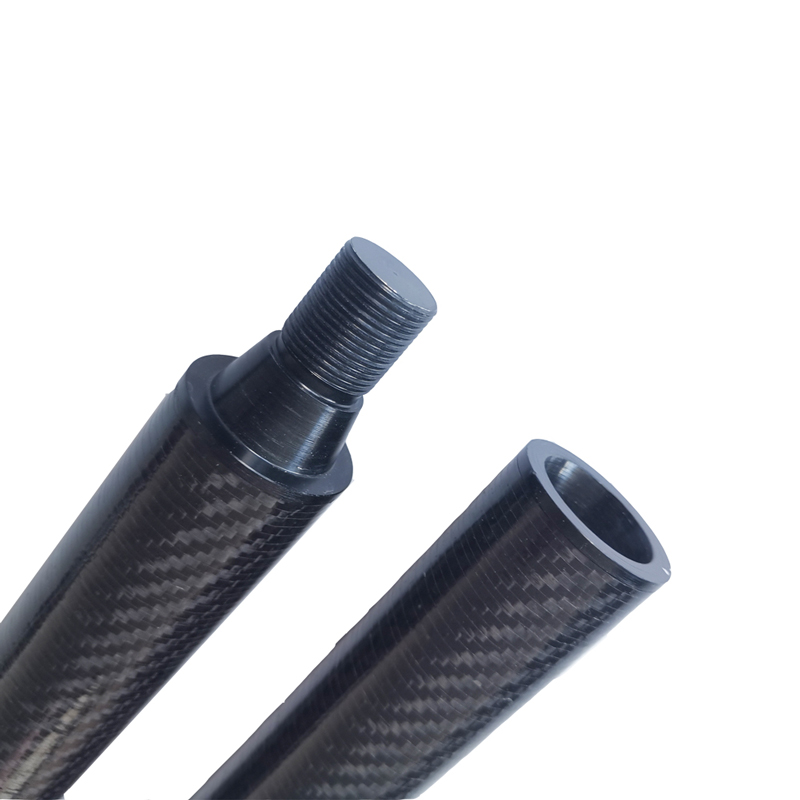

Each carbon tube normal tolerance we are in +- 0.1-0.2mm, we will measure carbon fiber pole before we sending to guarantee they are correct diameter

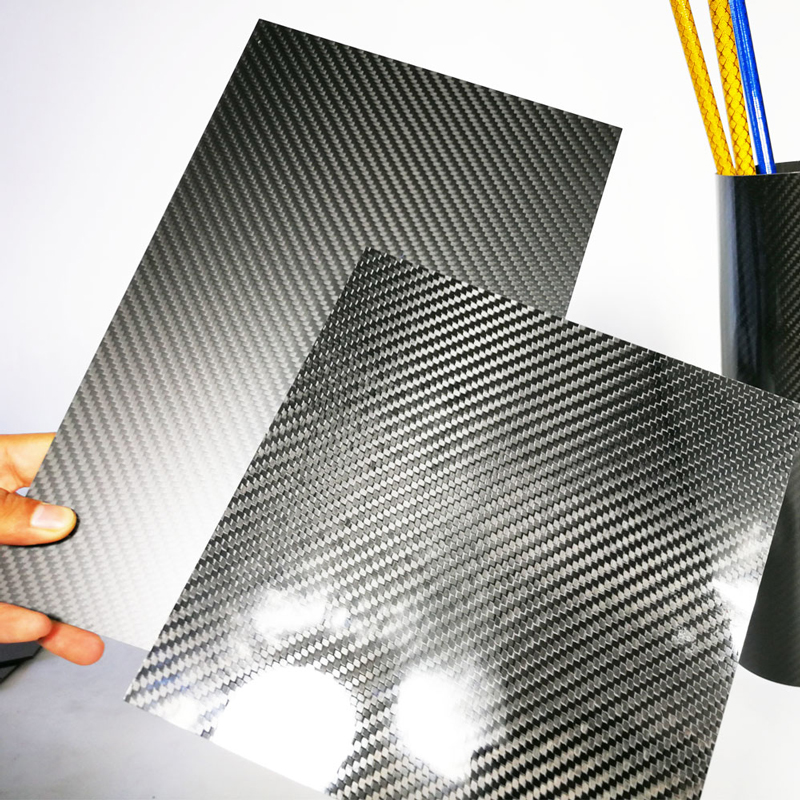

Also our carbon fiber weave is very nice and clear and no faded or scratch

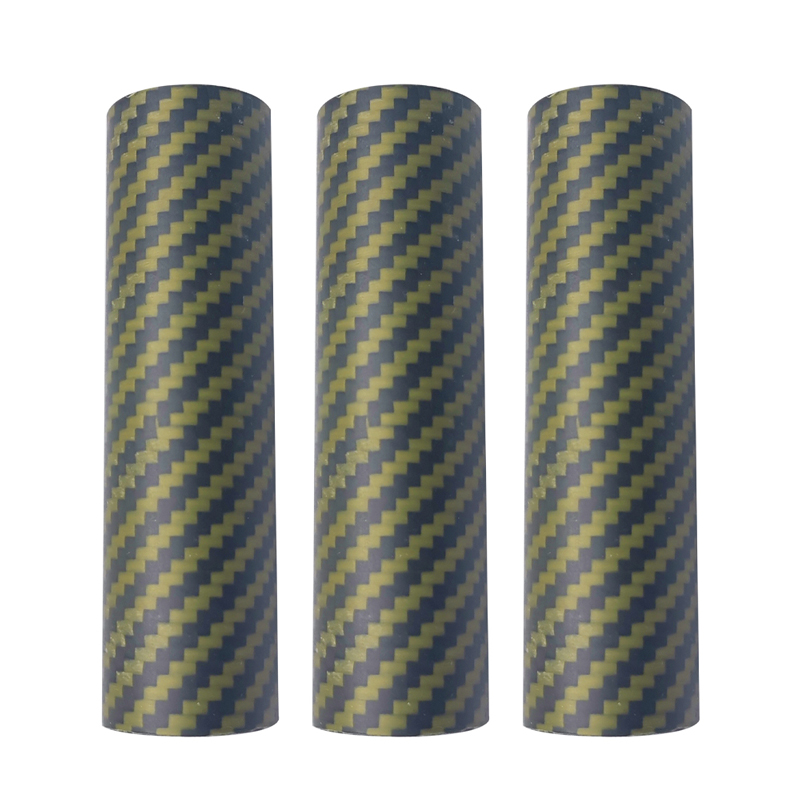

We can offer different carbon tube weave for optional

Our Team

Customer Praise

Customers from all over the world and we have become business partners.

They are come from different filed:industrial sport music energy cars electric Etc.

They are very passionate about carbon fiber products and sharing. They are growing and growing because of the products and

services we provide CONTACT US lets be partners !

Product detail pictures:

Related Product Guide:

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for New Arrival China Carbon Fiber Tube 19mm - Carbon Fiber Solid Tube Pultruded Carbon Fiber Rod Pipe – Snowwing , The product will supply to all over the world, such as: United Arab emirates, Iran, Serbia, we are sincerely hope to establish one good long term business relationship with your esteemed company thought this opportunity, based on equal, mutual beneficial and win win business from now till the future.

We are a professional chinese manufacturer of carbon fiber.and also carbon fiber products for more than 10 years!

we produce alltype carbon fiber tubes,panel,bars,rods,CNC sheet Etc excellent properties include: corrosion resistance lightness good toughness If you want order our products, please include ID, OD, length, dimensional tolerances, quantity, structural requirements, surface finish, surface pattern, material (if you know), temperature requirements, pocesing technology etc. With these items as the starting point, we can usually very quickly put together a quotation to help you get your project from idea to reality.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.