Products

CNC drilled Forged Carbon Fiber Tube 3k Carbon Fiber Pole

Products Categories

Carbon Tube Description

Carbon fiber tubes are produced by wrapping pre-impregnated (pre-preg) carbon fibre under tension around a mandrel, and then cured in a specialist oven. This produces a very consistent and high quality finished tube for many different applications such as building or repairing UAV's, robotics and RC products and outdoor products.

Carbon fiber tubes are used in numerous applications like tactical ladders, trusses, bridge,Car, and more. Carbon fiber is typically chosen over traditional materials such as aluminum, steel, and titanium because of the following properties:

High strength and stiffness to weight

Excellent resistance to fatigue

Dimensional stability: Low CTE (Coefficient of Thermal Expansion)

Resistance to corrosion

X-Ray transparency

Chemical resistivity

carbon Fiber Tubes can be sourced in many different sizes to those shown - please get in touch if you require a different or custom size.

Dimension Table

| 5*4 | 12*11 | 16*11 | 18*17 | 20*20 | 25*13 | 29*27 | 36*34 |

| 6*4 | 13*10 | 16*12 | 19*11 | 22*16 | 25*15 | 30*22 | 37*29 |

| 6*5 | 13*11 | 16*13 | 19*12 | 22*17 | 23*19 | 30*23 | 37*33 |

| 7*4 | 14*8 | 16*14 | 19*13 | 22*18 | 25*20 | 30*25 | 37*34 |

| 7*5 | 14*10 | 16*15 | 19*14 | 22*19 | 25*21 | 30*26 | 38*35 |

| 7*6 | 14*11 | 17*7 | 19*15 | 22*20 | 25*22 | 30*27 | 40*38 |

| 8*6 | 14*12 | 17*13 | 19*16 | 22*21 | 25*23 | 30*28 | 42*40 |

| 9*7 | 14*13 | 17*14 | 19*17 | 23*14 | 26*23 | 31*30 | 43*41 |

| 9*8 | 15*10 | 17*15 | 19*18 | 23*19 | 26*24 | 31.7*33.38 | 50*47 |

| 10*8 | 15*11 | 18*10 | 20*12 | 23*21 | 26*25 | 32*30 | |

| 10*9 | 15*12 | 18*11 | 20*14 | 24*16 | 28*24 | 33*31 | |

| 12*6 | 15*13 | 18*12 | 20*16 | 24*18 | 28*25 | 35*30 | |

| 12*8 | 15*14 | 18*14 | 20*17 | 24*19 | 28*26 | 35*31 | |

| 12*9 | 16*8 | 18*15 | 20*18 | 24*20 | 28*27 | 35*33 | |

| 12*10 | 16*10 | 18*16 | 20*19 | 24*22 | 29*26 | 36*33 | |

|

Length:max length can make 4000mm |

|||||||

|

max OD diameter can make 400mm |

|||||||

Product Picture Display

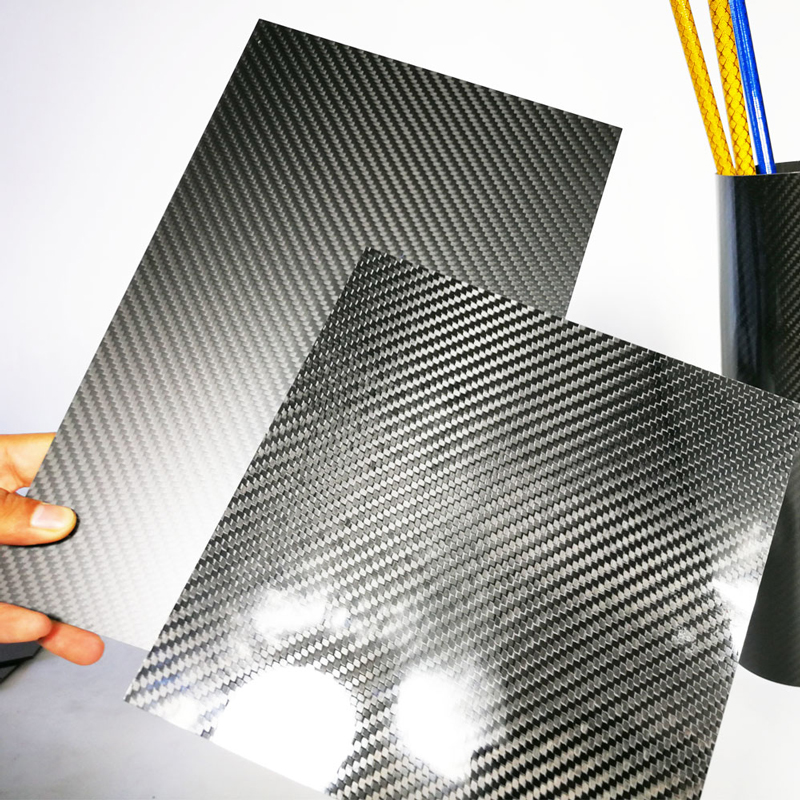

Material Style

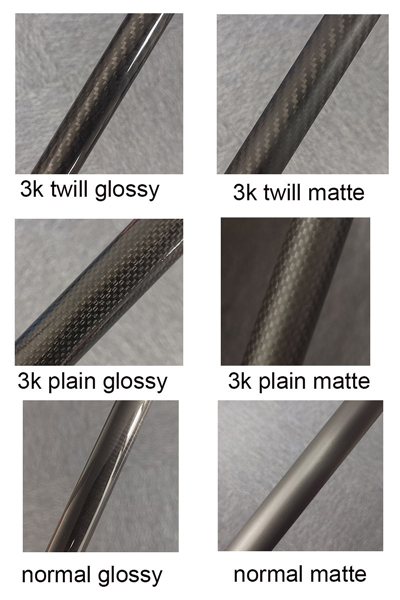

Carbon fiber tube surface

Can offer twill plain UD carbon fiber weave also with colorful carbon tube

And for surface we can offer glossy/matte/semi matte

Our surface is more stronger as we use high level painting to coat it,no faded or scratch easily.trust us we won't let you down

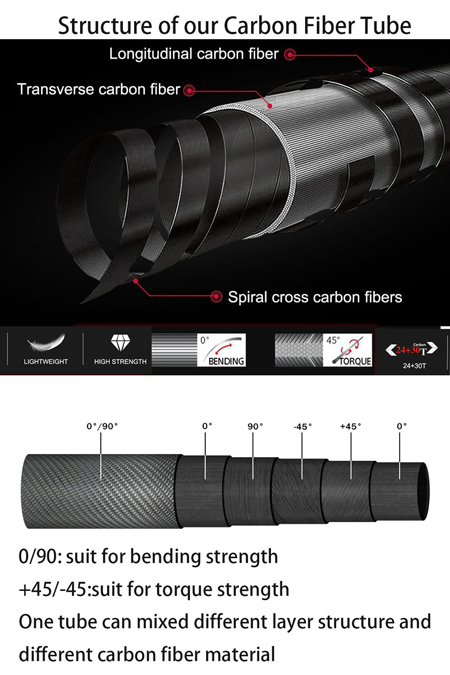

Process Technology

Carbon fiber tube rolling layers

From surface carbon fiber tube looks are same, but different carbon rolling layers direction will let carbon tube strength different,

if use for decoration

0-90° just simple rolling tech is enough this tube won't be undertake heavy weight

If use for industry or car or other filed, it need have very good strength

0 - 90 +45 -45°mixed layers can offer good strength for your usage

So if you could tell us your usage our engineer can recommend good carbon tube layers for you.